VISION:

"To be the centre of excellence in providing education in the field of Mechanical Engineering to produce technically competent and socially responsible engineering graduates"

MISSION:

"Educating students to prepare them for professional competencies in the broader areas of the Mechanical Engineering field by inculcating analytical skills, research abilities and encouraging culture of continuous learning for solving real time problems using modern tools"

Program Educational Objectives(PEOs)

The graduates will be able to:

PEO1:

Acquire core competence in Applied Science, Mathematics and Mechanical Engineering fundamentals to excel in professional career and higher study.

PEO2:

Design, demonstrate and analyze the mechanical systems which are useful to society.

PEO3:

Maintain professional & ethical values, employability skills, multidisciplinary approach & an ability to realize engineering issues to broader social context by engaging in lifelong learning.

Program Specific Outcomes(PSOs)

The graduates will be able to:

PSO1:

Implement the basic Mechanical Engineering knowledge to solve societal and industrial problems.

PSO2:

Design and Analyze basic Mechanical system using relevant tools and techniques.

PSO3:

Understand and address current issues of industries through industry institute interaction and alumni social networks.

About Department:

The Mechanical Engineering Department started with the inception of the college in

the year 1996. The department offers Undergraduate and Research Programs. The

Mechanical Department has been approved as a Research Centre by Visvesvaraya

Technological University, Belgaum to offer Ph.D. programs in the year 2014. It has

well-equipped Laboratories with state-of-the-art types of equipment and

infrastructure facilities in thrust areas. The department has a total investment of

Rs.1.3 crores. The mission of the department is to educate students to become

globally competent. The Department of Mechanical Engineering shares the vision and

mission of the institution in imparting quality education to the students.

The department has an intake of 60 and a total strength of 140 students. The

mentorship concept is introduced in the department to monitor their performance and

guide them effectively through periodic counselling. The students of the department

are well-placed in industries and have established themselves as successful engineers

for many years. Apart from the achievement in the academic performance the

students of our department have presented papers in various National level

competitions and brought laurels to the college by winning the awards. Several

students’ projects have won National/State/Intercollegiate awards for their projects in

competitions held at different organizations. Students have also qualified for many

national-level examinations such as GATE and are very well placed in National and

Multi-national companies. Some of them have pursued higher studies in India and

abroad. Mechanical Department students visited many Industries for industry

orientation. All students undertook internship training in reputed companies. Students

participated in various sports & cultural activities together with some important

technical events. The department alumni students are extending guidance and support

in guest lectures and placement. The department has a committed, highly experienced

and motivated team of faculty members. All the staff members are postgraduate and

have been serving in the institute for more than ten years. Many faculties of the

department are undergoing Doctoral programs. Faculty members regularly attend

technical seminars and workshops organized by various technical institutes, and

many of them have presented papers at National and International conferences and

seminars. An association of Mechanical Engineering students and staff has been

constituted in the department named AIMSS and is involved in arranging expert

lectures, and co-curricular and extracurricular activities.

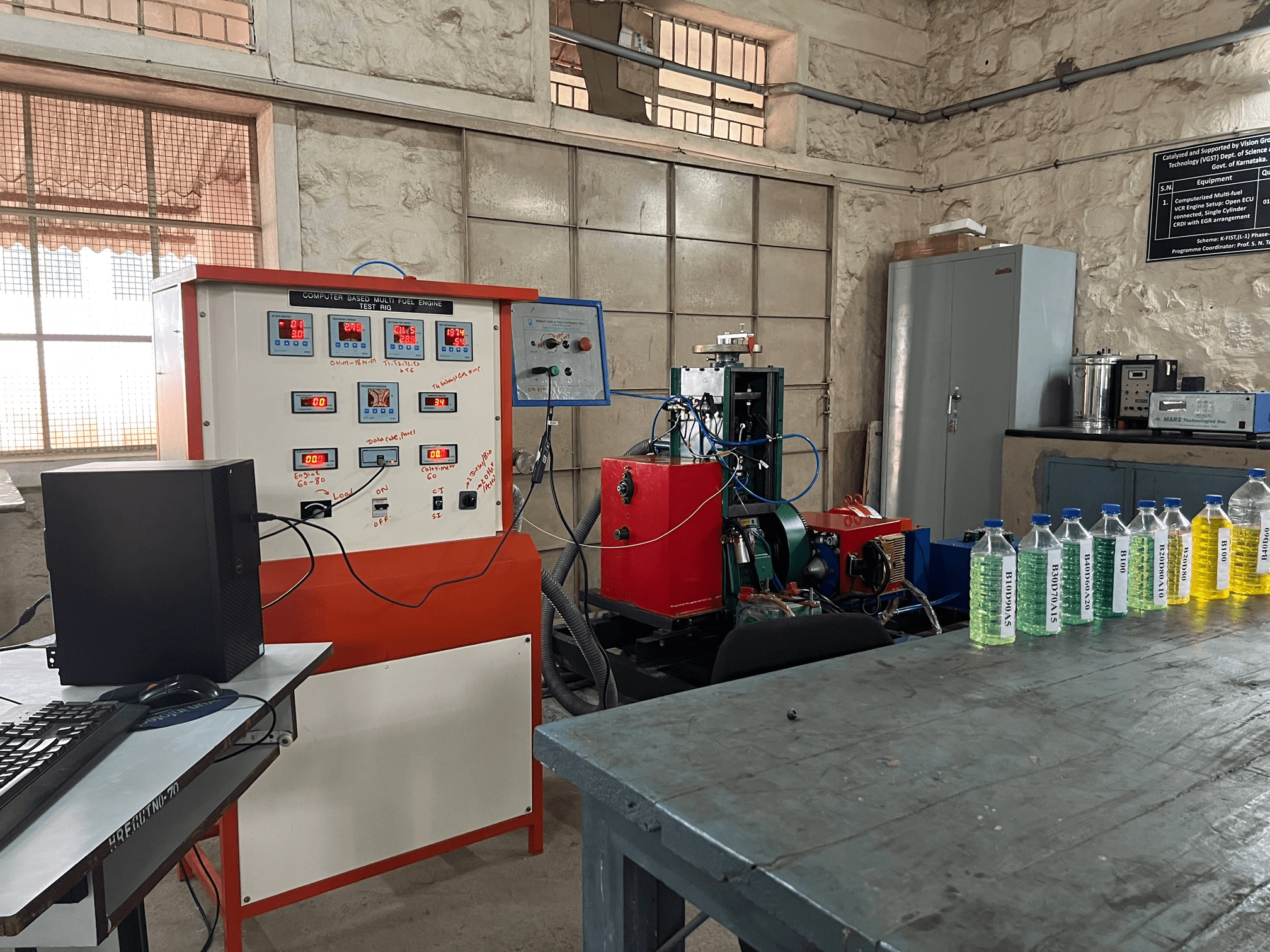

The department received a grant of Rs. 60 Lakhs from VGST during the years 2022-

23, 2018-19, and 2013-14 for the research work. Also, the Department received 1.5

lakhs Unnat Bharat Abhiyan (UBA) Prime Minister Flagship program. One week

Short Term Training Programme was organized by the department on the topic

“Computational Fluid Dynamics” sponsored by ISTE-SRM, New Delhi with a grant

of Rs. 1 lakh in the same year. Several students’ projects have been funded by

KSCST, ISSRD, VGST and other private bodies in the region. The Department of

Mechanical Engineering has MOUs with 05 leading & reputed industries of

Karnataka & Maharashtra states. The department has a professional body membership

with ISTE and arranges the activities under the banner of ISTE. The department has a

well-stocked library with 2000+ text and reference books for the students and staff

fraternity.

Career Prospects

Mechanical engineers provide efficient solutions to the development of processes and

products, ranging from small component designs to extremely large plants, machinery

or vehicles. They can work on all stages of a product, from research and development

to design and manufacture, through to installation and final commissioning.

Most industries rely on a form of mechanical systems and mechanical engineering is

thought to be one of the most diverse of all engineering disciplines. The Mechanical

Engineers work on recent Technologies such as EV, AI & ML, Robotics, and

Mechatronics. There are employment opportunities also available in a wide range of

sectors, such as Manufacturing, Automobile Power, Construction, etc. Mechanical

engineers can also be involved in the management of people and resources, as well as

the development and use of new materials and technologies.

Laboratory Facilities Provided

• Computer Aided Engineering Drawing Lab

• Computer Aided Machine Drawing Lab

• Computer Aided Modeling and Analysis Lab

• CIM and Automation Lab

• Python Lab

• Artificial Intelligence and Machine Learning (AI & ML)

• Design Lab

• Heat & Mass Transfer Lab

• Metallography & Material Testing Lab

• Mechanical Measurement & Metrology Lab

• Fluid Mechanics & Machines Lab

• Energy Lab

• Machine Shop Lab

• Foundry & Forging Lab

• Project and Workshop Lab

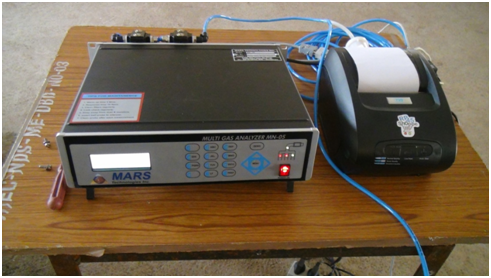

Research Facilities:

• Computerized IC Engines

• Biodiesel Plant

• Wind Tunnel

• Gas and Smoke Analyzers

• Bosch Industry attached lab

• Idea and Coding lab

Courses Offered:

• B.E. Mechanical Engineering

• Ph.D. in Mechanical Engineering